Pipe Supports

Petrovision International offers pipe supports from LISEGA. With the world’s most comprehensive product range, you can find the right support solution satisfy the requirements at the highest technical level. LISEGA’s pipe supports are used in a variety of industrial plants.

We Offer Pipe Supports from LISEGA

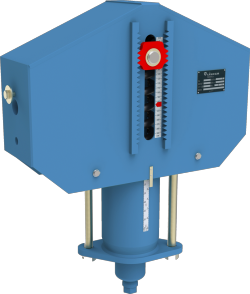

Constant Hangers & Constant Supports

Constant hangers & Constant supports are used for piping and related components where higher levels of vertical travel occur.

Benefits

- Symmetrical design

- Favourable power-weight ratios for reduced installation loads.

- Consistent functional behaviour due to high-quality corrosion protection and maintenance-free, chemically nickel-plated finishes.

|

Hangers and Spring Supports

They are used to balance slight vertical displacements in the pipe system. It comes with many features

- Five travel ranges from 0 to 400 mm / 0 to 15.75 in, load group C to load group 9.

- Modular system simplifies selection (load groups and travel ranges).

- Torque-free load application by covering the load and symmetry axis.

|

Dynamic components

LISEGA snubbers are characterized by superior functionality and durability. The function of LISEGA hydraulic snubbers type 30 is controlled by a main control valve positioned axially in the hydraulic pistol. It comes with

- Corrosion-resistant materials

- Radiation-resistant and wear-resistant sealing systems

- Vibration-resistant guides

- Pressurized hydraulic system for optimal sealing

- Dynamic functional behavior

- Types offered-

- Snubbers type 30

- Snubbers type 31

- Rigid struts type 39

- Energy absorber type 32

- Viscoelastic dampers type 3D

- Pipe whip restraints type 3R

- Dynamic clamps type 34,36, 37

|

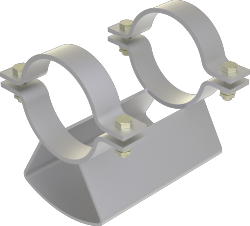

Pipe clamps, clamp bases, pipe clamps, clamp bases, pipe connections

Pipe clamps, pipe bearings, pipe weld-on lugs and U-bolts all belongs to the category of pipe connections. You can find the optimal design for every application from Lisega.

Benefits

- Superior quality

- Design in accordance with applicable regulations

- Ensures maximum operational safety

- Complete and clearly structured data tables

|

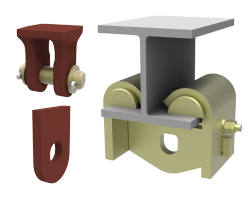

Roller Bearings, Pipe Saddles and Cryogenic Pipe Supports

Roller bearings are the optimum solution for pipe systems of larger diameters that are subjected to high loads. They feature high load-bearing capacity, great reliability and extremely low friction resistance.

- Simple and safe design of lift-off restraints

- Pipe saddles allow for convenient load transfer into the tube wall

- Pipe saddle design minimises heat transmission

- Hot-dip galvanised corrosion protection in all roller bearings

- Maintenance-free operation

- Roller axle made of stainless steel

- Teflon-bronze composite bushings

|

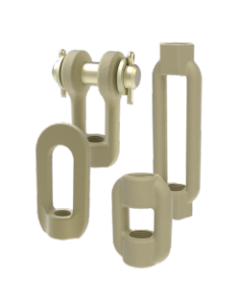

Connection Components

Connection components are prerequisites for the reliability of the entire load chain. They are specially shaped bolting components for connecting rods to other support components. They connect components in the load chains with their counterparts, such as lugs, U-bolts or eyelets.

- Load and connection compatibility with the LISEGA modular system<l/i>

- Drop-forged and heat-treated

- Galvanised as standard, hot-dip galvanised upon request

- Approval through special type tests

|

Structural Attachments, Slide Plates

Special components for welding or clamping are available for connecting the pipe supports to the supporting structure.

Designs

- Beam clamps type76

- Beam clamps type78

- Weld on clevises type 73

- Weld on Plates with spherical washers type 74

- Weld on eyelets type 75

|

Licad

Software for support design. With LICAD software, you can generate support drawings, bill of materials and 3D models in different CAD programs. The parameters that are required to find the optimum support design solution:

- Pipe diameter

- Temperature of medium

- Operating load

- Displacement

- Installation height

- Support configuration

|

For more information about the different products we offer, call +968 2448 2137 / 2138.